FRIENDLY CT-AQ100H

FRIENDLY CT-AQ100H

- Processing capacity of 100L/H

- High concentration Rate

- New system design

- 24 hours automatic continuous operation

- Excellent usability

Amount of discharge of wastewater is reduced sharply

Conventionally, wastewater generated in a production site has been processed by requesting to an industrial waste disposal company. The amount of wastewater in which an industrial waste disposal company takes over such a present condition is sharply reducible by introducing FRIENDLY without spending big expense.

Concentration Capacity of Waste-soluble Wastewater

* The concentration rate of water-soluble wastewater changes by the ratio of mixed component.

High cost-effectiveness

Reference example

- Days of operation for 1 month: 25 days

- Days of operation for 1 year: 300 days

- Discharge amount of wastewater: 1000L/ D

- Industrial waste disposal rate: JPY50/ L

Before installation

Wastewater disposed by an industrial waste disposal company

Amount of wastewater

Amount of wastewater for 1 month: 25,000L

Amount of wastewater for 1 year: 300,000L

Industrial waste disposal expense

Disposal expense for 1 month: JPY1,250,000

Disposal expense for 1 year: JPY15,000,000

After installation

FRIENDLY:CT-AQ100H

Ex) Concentration rate: 10 Times / Electric rate: JPY14.9 /kwh

Amount of wastewater

Amount of wastewater for 1 month: 2,500L 1/10

Amount of wastewater for 1 year: 230,000L 1/10

Electric rate

Usage for 1 month: JPY94,105(Approx. JPY3764.2 per day)

Usage for 1 year: JPY1,129,260

Antifoam agent

Month’s purchase: JPY54,250

Year’s purchase: JPY651,000

When renovated water meets environmental quality standards for sewage, it can be drained into sewage system. Furthermore, it leads to cost mitigation of water cost by reusing.

Cost comparison

Before installation

JPY1,250,000/ month

JPY15,000,000/ year

After installation

JPY273,355/ month Cost difference JPY976,645/ month

JPY3,280,260/ year Cost difference JPY11,719,740/ year

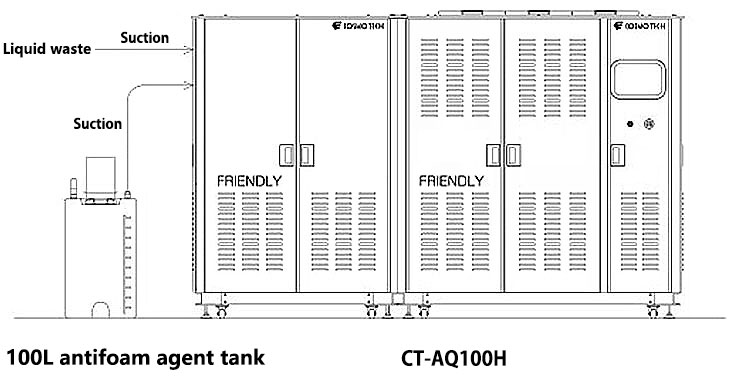

System Configuration (Standard Specification)

Specifications

| Name | Aqueous Liquid Waste Treatment System FRIENDLY |

|---|---|

| Model | CT-AQ100H |

| Capacity | 100L/h |

| Treatment scheme | Reduced-pressure distillation method |

| Control method | Heat pump type |

| Target liquid waste | Water-soluble liquid |

| Power supply | 3相 200V 50/60Hz |

| Electric power capacity/ Current | Approx. 34.7KVA/ 100A |

| Input breaker | 125A |

| Operating condition | Ambient air temperature: 5-35℃, Humidity: 0-60% Non condensing |

| Product weight | Approx. 1400Kg (Operation weight: Approx. 1730kg) |

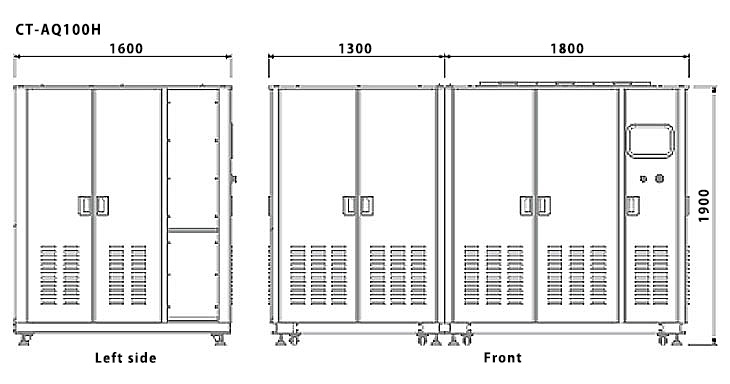

| Dimension (W×D×H) | 3100×1600×1900 mm (2 Units W1800/W1300) |

| Standard accessories | Liquid waste tank (500ℓ)×1 Antifoam agent tank (100ℓ)×1 Liquid waste intermediate tankx1 Instruction manua×1 |

| Consumables | Antifoam agent (When required)* |

* Antifoam agent: (We recommend you to use our recommended agent.)

Options

- Liquid waste intermediate tank (For additions)

- Renovated water intermediate tank

- Concentrated liquid waste intermediate tank

- Renovated water pH display

- Renovated water pH control (aeration)

* It needs to be adopted with the renovated water pH display. - Renovated water coloring detection sensor

- Conductivity detection sensor

- Automatic water supply function

- Liquid waste tank (For additions) 200L/300L/500L (With float sensor & SUS strainer)

- Liquid waste tank (Agitation pump type) 300L/500L (With water level sensor & SUS strainer)

- Liquid waste tank (Floating oil recovery type) 200L/300L/500L (With water level sensor & SUS strainer)

* There is the function which cannot be added by the model.

* The numerical value of the processing capacity mentioned above is alibity at the time of using freshwater. There is a case varying in processing capacity depending on actual liquid waste.

Dimensional drawing