FRIENDLY-UF

独自の分離膜技術で廃液量の大幅な減容化を実現

近年、機械加工など様々な現場において安全性・冷却効果・作業環境の改善から水溶性油剤が使用されています。これらの水溶性油剤は通常、水で5~10倍程度に希釈されており、現在使用される加工油剤の90%は水溶性油剤と言われております。しかし、使用後の含油廃液は難処理性が高く、その大半がそのまま産業廃棄物となっているのが現状で、その焼却処理時には大量のCO2を排出しています。

FRIENDLY-UFは、独自の分離膜技術を活かし水溶性含油廃液を確実に分離濃縮させ大幅に減容化を計り、「環境保護」「コスト削減」をサポートします。

特徴

- 吸着剤・凝集剤等を使用せずに乳化した油分を確実に分離濃縮できます。(99%除去)

- 廃液量を1 / 10 ~ 1 / 20まで濃縮減容ができます。 ※ 廃液の種類・濃度によって異なります。

- 廃液の分離濃縮により大幅な産廃費用の削減が計れます。

- 清浄な透過液は回収し再利用ができるため環境に優しく経済的です。

- 分離膜は洗浄が可能でロングライフなご使用ができます。

- 特殊分離膜処理のため、スラッジの発生がありません。

- 全自動運転でどなたでも簡単に操作ができます。

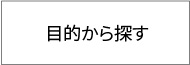

分離膜の原理

独自の分離膜技術で油廃液を確実に分離

含油廃液を多孔性ファイバーの内面に密着された分離膜に通過させることで、水(低分子・イオン含む)だけが透過し、油分(高分子・濁質含む)と分離します。分離膜内は高乱流状態となっており、高い透過率を維持しながら目詰まりを起こさない安定的な処理が可能です。また、定期的なスポンジボールによる物理的自動洗浄や、状況に応じた薬品洗浄を行うことで分離膜は常に綺麗な状態を保つことが出来ます。この分離膜は耐熱性・耐薬品性にも優れており、多様な用途でご使用いただけます。

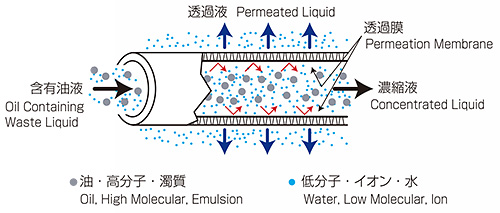

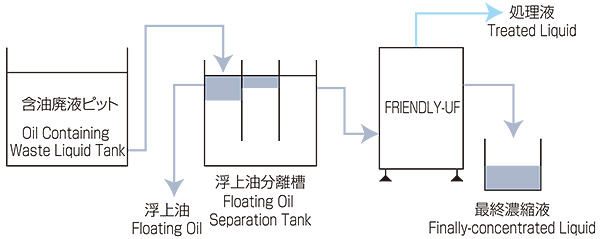

システムフロー

洗浄廃液

切削廃液

原液は分離膜を通過することで水(低分子・イオン含む)だけを透過し、濃縮液は再度原液槽へ戻されます。

連続的に原液を循環することで透過液だけが抜き取られ、原液は1 / 10 ~ 1 / 20まで濃縮減容します※。

透過液が排出されるに従って原液槽の水位は低下し、目標水位に到達した時点で運転は終了します。

※ 廃液の種類・濃度によって異なります。

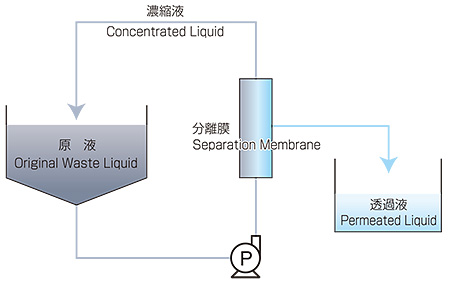

設置例

場所を選ばず、目的に合わせた最適な処理が行えます。

連続処理

バッチ処理

再利用(リサイクル)または、最終処理(FRIENDLY※や既設浄化槽)による下水放流

※ FRIENDLY ・・・ 減圧蒸留方式の水溶性廃液処理装置

用途

様々な加工プロセス工程で排出される廃液の処理に有効です。

洗浄廃液・切削廃液・研磨廃液・コンプレッサードレン廃液・洗車廃液・ダイカスト廃液・高周波クーラント廃液・圧延クーラント廃液など

仕様

| 機種名 | FRIENDLY-UF |

|---|---|

| 膜面積 | 0.65m2(長さ750mm) |

| 重量 | 80kg(空水時) |

| 電源 / 容量 | 三相200V / 1.5KW |

| 運転圧力 / 流量 | 0.5~0.6MPa / 20~30L/min |

| 目安処理能力 | 15L/h~25L/h |

| 耐熱 | 60℃ |

| 本体寸法(W×D×H) | 730×995×1617mm |

| 外部入力 | 装置停止信号 |

| 外部出力 | 一括異常信号 原液供給信号 濃縮液排出中信号 |

シリーズ一覧表

| 機種名 | FRIENDLY-UF シリーズ | |||||

|---|---|---|---|---|---|---|

| 膜面積(m2) | 0.9 | 1.8 | 2.7 | 3.6 | 4.5 | 5.4 |

| 重量(空水時)(Kg) | 180 | 220 | 280 | 320 | 380 | 420 |

| 電源 / 電圧 | 三相 200V 50 / 60Hz | |||||

| 電気容量(KW) | 3.5 | 3.5 | 4.5 | 4.5 | 8.0 | 8.0 |

| 運転圧力(MPa) | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 |

| 流量(L/min) | 20~30 | 40~60 | 60~90 | 80~120 | 100~150 | 120~180 |

| 目安処理能力 (L/h) | 25 | 50 | 75 | 100 | 125 | 150 |

| 耐熱(℃) | 60 | 60 | 60 | 60 | 60 | 60 |